Quality assurance of adhesive and glue is the way to prevent the detective and the problems in the quality of services and product. Through systematic monitoring can reduce human negligence.

There are three different ways for us to execute Quality Assurance.

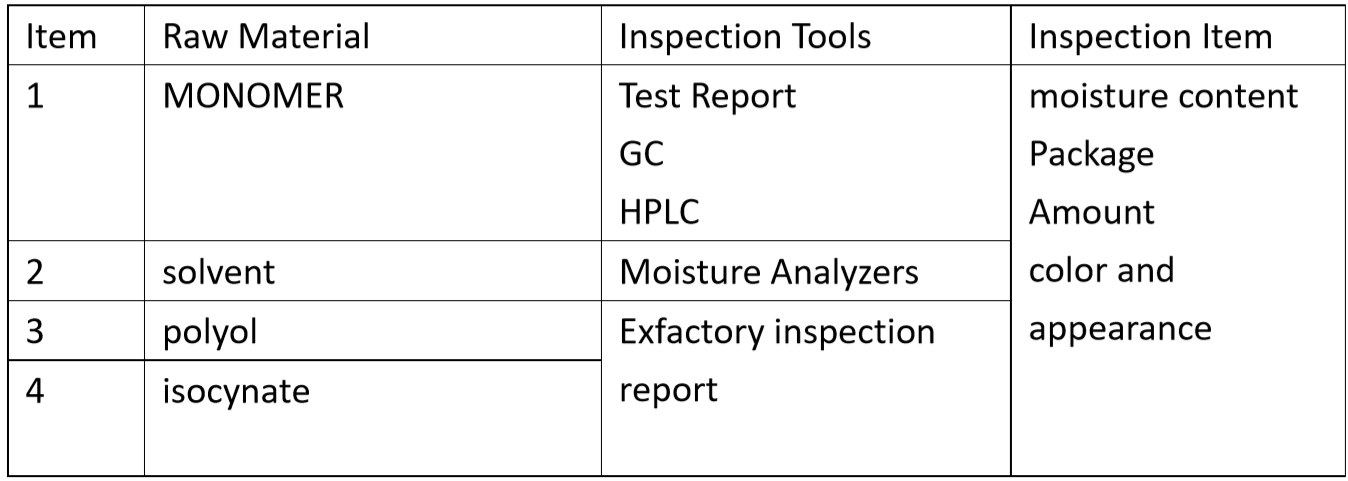

IQC

Through the IQC(incoming quality control) can ensure that the quality of raw materials meets the standard of the manufacturing department. In addition, each batch of inspection results will be recorded on the documents. Strict incoming inspections effectively reduces the chance of using defective products, therefore reducing the ratio of rework and control the costs. All of the defective products will be stick on a label and be moved to return or scrap areas.

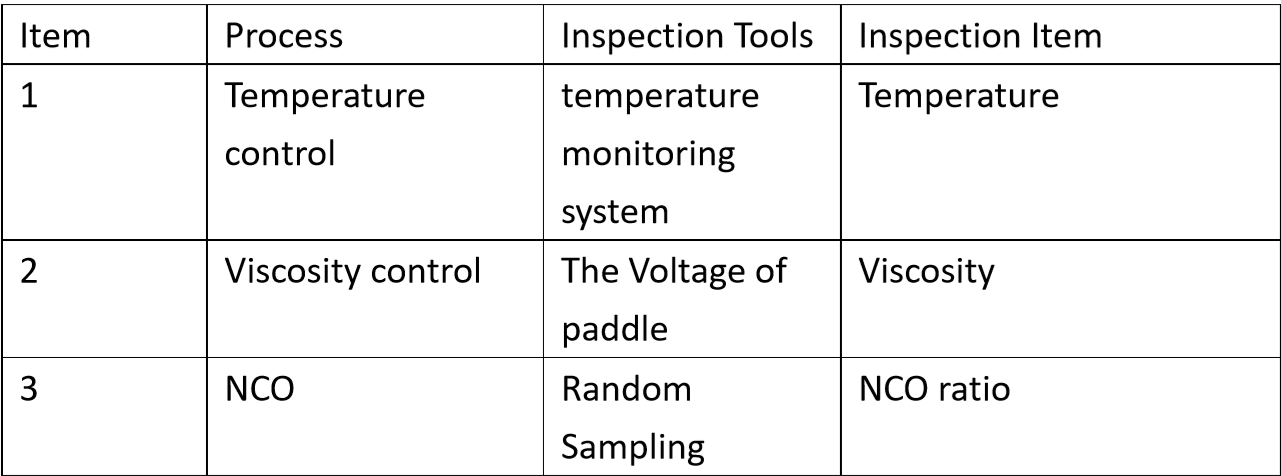

IPQC

IPQC (InPut Process Quality Control) inspection process will make sure that the correct materials and correct environment are used in production. At the same time, the process would meet the safety operating standards and all inspection and confirmation items will be recorded.

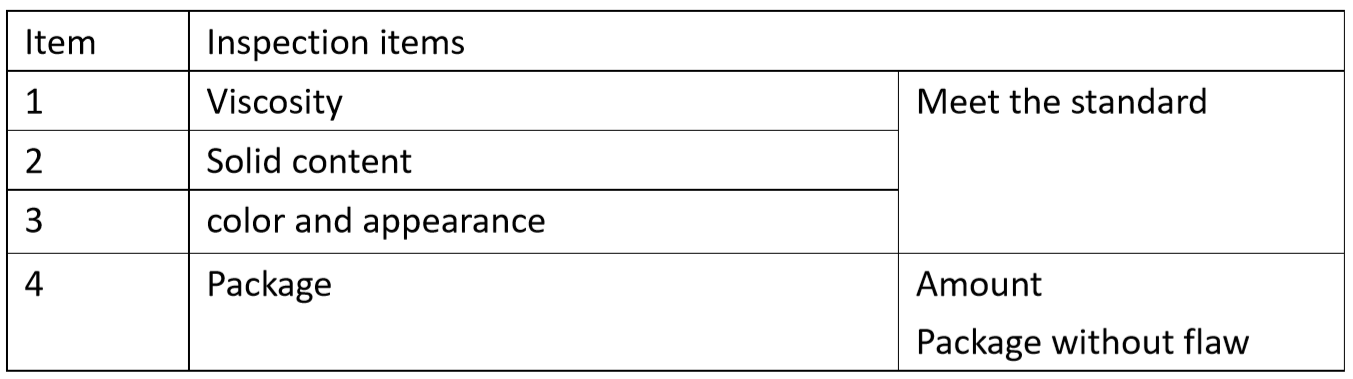

FQC

FQC(Final Quality Control) inspection can ensure that customers receive good quality products. All inspection result with one set of samples will be preserved in the storage room.

Please contact us for a free sample of the adhesive, only a courier fee is charged.