What is the rolling ball tack test?

The rolling ball tack test stands as a pivotal method to assess the initial tackiness of adhesive surfaces. This comprehensive guide delves into the principles, procedure, and importance of the rolling ball method in evaluating adhesive stickiness and its practical applications.

Understanding the Rolling Ball Tack Test:

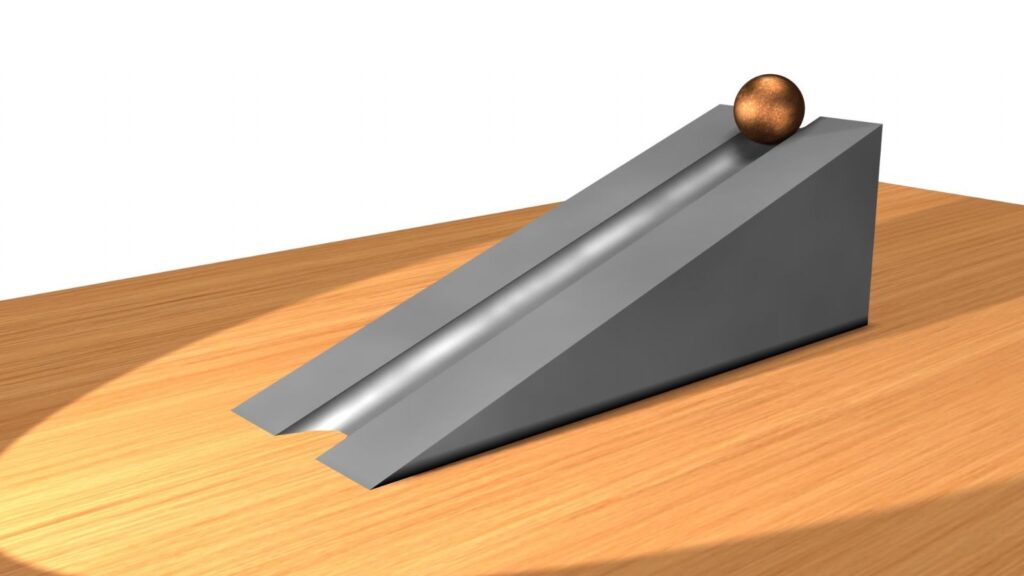

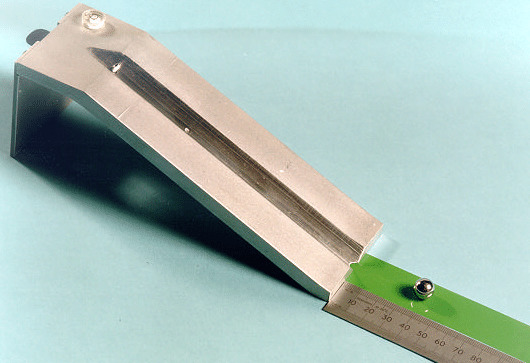

The rolling ball tack test involves rolling a standardized ball down an inclined plane onto an adhesive-coated surface. The distance the ball travels on the adhesive surface before halting or reaching a defined velocity quantifies the adhesive’s initial tack.

Procedure:

Testing environment condition: 25±2℃, 65±5%RH

Notice: Clean the surface and the stainless ball well with EAC before testing.

- Surface Preparation: Apply the adhesive uniformly on a flat surface.

- Inclined Plane Setup: Arrange an inclined plane at a specific angle.

- Ball Release: Release a standardized ball down the incline onto the adhesive surface.

- Measurement: Measure the distance the ball travels before stopping on the adhesive-coated surface.

Significance and Applications:

- Tack Assessment: The shorter the distance the ball travels, the higher the adhesive’s initial tack, which is crucial in applications requiring quick bonding upon contact.

- Comparative Analysis: Enables comparative analysis between different adhesive formulations or surfaces to determine optimal adhesive performance.

The rolling ball tack test offers a simple yet effective way to quantify the initial tackiness of adhesive surfaces. Understanding this method’s principles assists in assessing adhesion performance, aiding industries reliant on quick adhesion for various applications.